Three Arrows’ strength lies in our revolutionary product procurement method that defies conventional apparel industry wisdom, known as Direct Clothing Operations (Factory-Direct Clothing Sales).

Three Arrows is a fresh new clothing wholesaler established in October 2015. Using our weapons of rich product knowledge and a strong pipeline to overseas sewing factories, we have constructed our own original product procurement method that links overseas factories and retailers directly, enabling major reductions in procurement costs.

Another major strength is our ability to provide products through an integrated system of dispatch and distribution in addition to planning proposals tailored to customers detailed needs, and we are gathering broad support from retailers throughout Japan.

Three Arrows carries out product planning and design in Japan and product manufacturing at reliable sewing factories located overseas. We are the only company that has achieved the complete integration of general apparel business activities, from distribution and product inspections/checks overseas to product importation and distribution/delivery within Japan. We refer to this new product procurement method as Direct Clothing Operations (Factory-Direct Sales), and it is our greatest strength—one that no other apparel maker or textiles trading company has—enabling us to propose better quality products for greatly reduced merchandise costs. By eliminating unessential product costs and delivery costs, we are achieving reductions in our cost base of a maximum of more than 30%.

In conventional distribution routes, products manufactured in overseas factories are transported from Japanese ports to warehouses and then delivered to stores after apparel makers/textile trading companies have carried out shipping procedures. In contrast, Three Arrows sends products manufactured at factories overseas to the port closest to our trading partner, and the initial delivery is then delivered as-is to each store. For additional orders, the products are transferred from the port to a subcontracted warehouse and then delivered to stores as required. This simplification of delivery routes from factories to stores also contributes to the reduction of CO2 emissions.

In this way, Three Arrows has constructed a completely new manufacturing system that is well able to adapt to new circumstances and avoids stereotyping.

We also provide product proposals that take into consideration the selling floor space allocation for each individual end-user, in addition to developing new brands; registering trademarks; producing small lots of around 300 items/carrying out quick production, including for test sales; undertaking OEM production for trading partners’ private brands; and a broad range of other services. We can also provide information about overseas factory production status and the local situation as well as production information for both Japanese and overseas brands.

Passion for manufacturing

Focusing on men’s clothing items, Three Arrows undertakes the development and production of a wide range of apparel products. We operate under a 100% made-to-order manufacturing system whereby we only manufacture the quantity of items ordered by each retailer. Of the many products that we supply, an item into which we pour especial effort is men's blouson jackets. These jackets entail a far more complex and difficult production process than cut-sew or other clothing items, and there are no specialist manufacturers. Moreover, because these jackets are also difficult for retailers to produce themselves, they are an item category for which there is little competition. Through our independent network of overseas factories established over many years, Three Arrows has built a system enabling us to supply high-quality blouson jackets at low prices. We are, therefore, able to propose good quality blouson jackets for low prices.

Three Arrows has concluded production agreements with overseas sewing factories that clear our strict quality standards. Products ordered by our trading partners are manufactured on consignment. Factories are located in China, Myanmar, and Cambodia.

In addition to factories with special manufacturing equipment enabling the manufacture of products containing padding or down, we have concluded an agreement with a factory that is expert in the production of padded products, blouson, and pants, with a production capacity of 4.5 million items per year. We have also concluded agreements with factories that can flexibly accommodate small lot production. Thus, we have an all-mighty production system that can respond to a broad spectrum of needs, from orders for items requiring mass production to orders for small lots.

We outsource fabric and product inspections to a Japanese public testing organization, KAKEN Test Center, and Japan-related testing organizations overseas as part of our mission to provide customers with good-quality products that they can use safely with peace of mind and full satisfaction.

Inspections of fabrics and raw materials, such as down, are carried out preproduction in order to check product quality and safety ahead of production, and inspection items differ for each product.

Because such inspections are expensive and time-consuming, some companies carry out production without implementing them first; however, Three Arrows regards it as only natural that we should carry out inspections for each required item for every product, ensuring that all items have been cleared before production commences.

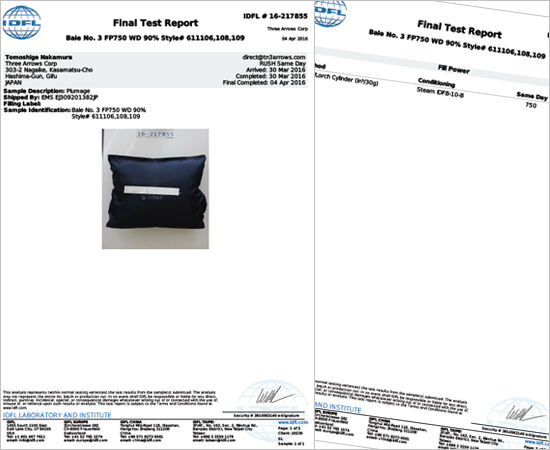

In particular, we outsource inspections of down materials to IDFL, a testing organization whose head office is located in Salt Lake City, USA.

Products manufactured by famous outdoor apparel brand products and sports brand products containing down are virtually all inspected at IDFL’s Salt Lake City head office and carry the IDFL inspection ratings and IDFL’s SKY BLUE trademark. Three Arrows products undergo the same careful testing.